For 3-32 mm Microducts,EN 50411-2-8:2009.

Product Advantages

For 3-32 mm Microducts.

Easy “push-in” installation.

Crystal clear transparent body.

Usage in DB(direct burial) scenarios.

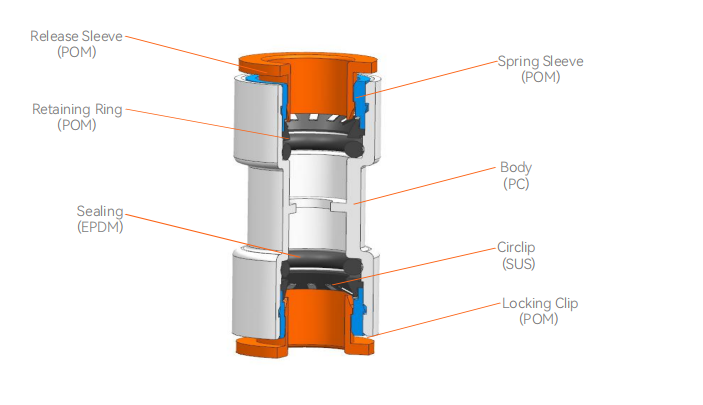

95% of the material is made of non-metal.

Tested in accordance to EN 50411-2-8:2009.

Locking rings to prevent accidental removal of connector.

Quantity

库存: 0

Product Specifications

| Construction | Description |

| Tube To Connector | HDPE Microduct( DB | DI | TW ) |

| Fluid | Air with blowing system |

| Working Pressure | 20 bar |

| Burst Pressure | 25 bar |

| Estimated Life | 25 years |

| Protection Class | IP68 |

| Water Ingress Test | 0.5 bar during 168 hours |

| Installation Temperature | -15℃ to +45℃ |

| Operation Temperature | -15℃ to +45℃ |

| Transport and Storage Temperature | -15℃ to +45℃ |

| Insertion Force | Size≤12mm,≤ 50 N | Size≥14mm,≤ 120 N |

| Impact Resistance | 1.5J |

| According To Standards | CEI EN 50411-2-8,EN 50411-2-5,EN61300,EN61753-1,EN60068-2-10,EN60794-1-2:2003 |

Product Structure

Product FAQ

What is the production capacity of Microduct Connector?

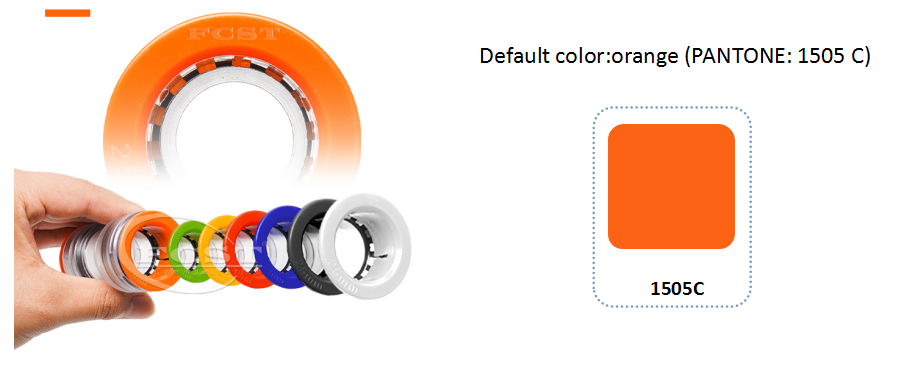

Which parts of Microduct Connector can be customized in color?

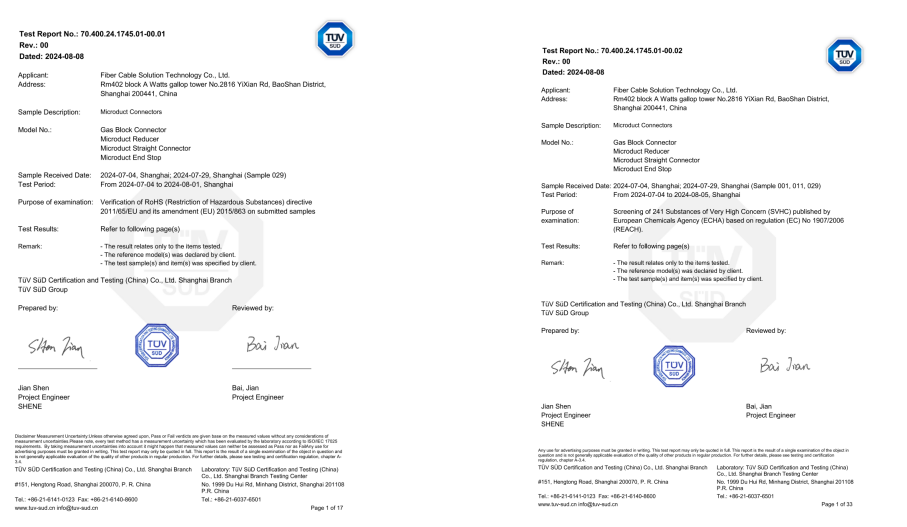

What environmental certifications do Microduct Connector comply with?

What industry standards do Microduct connectors meet?

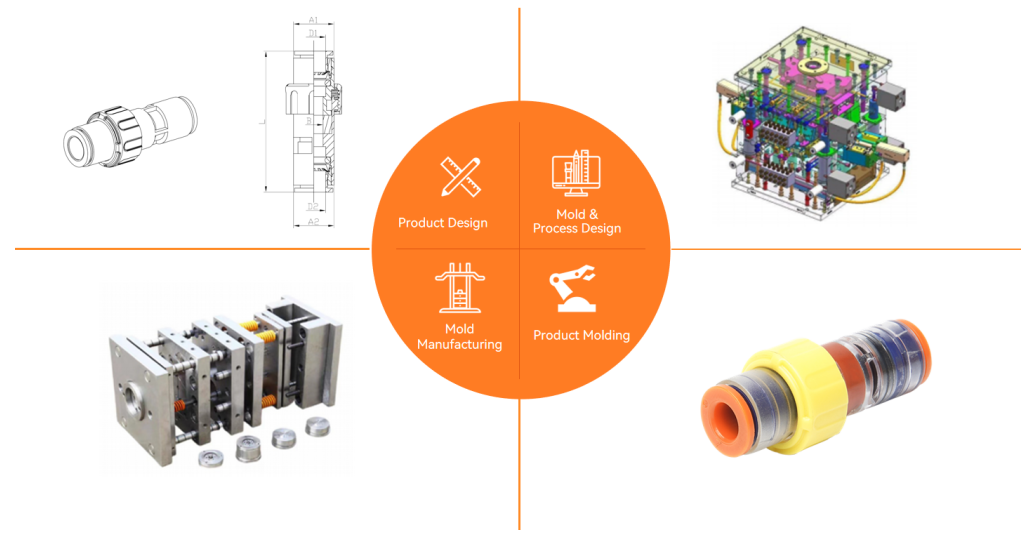

How long does it take to customize the Microduct connectors?

How much non-recycled material is used in the standard packaging of Microduct connectors?